Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

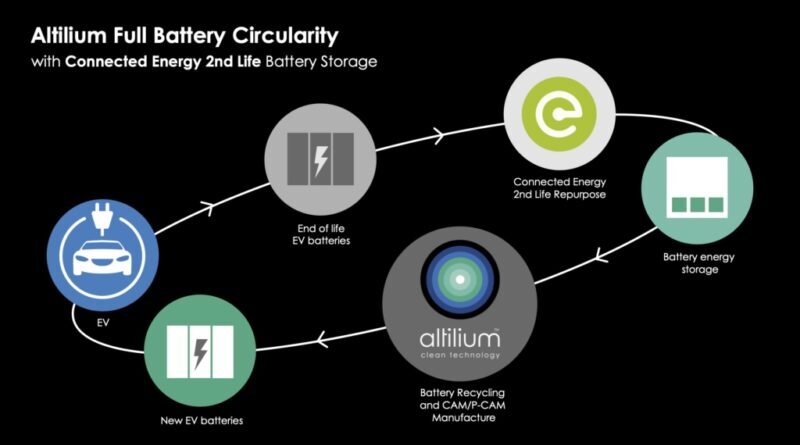

Altilium, a UK-based clean technology group focused on supporting the transition to net zero, and Connected Energy, a leading developer of second-life battery energy storage systems, have today announced a new strategic relationship that will see the two companies working together to extend the lifecycle of EV batteries.

The collaboration brings together two of the UK’s leading innovators in the fast-growing EV battery eco-system and underlines both companies’ commitment to sustainability and reducing the environmental impact of EV batteries.

Connected Energy designs and develops energy storage systems using second life EV batteries, while Altilium is a pioneer in EV battery recycling, processing end-of-life EV batteries and manufacturing scrap to produce low-carbon cathode active materials (CAM) for direct reuse in new batteries.

Under the agreement, Altilium and Connected Energy will collaborate to develop sustainable and environmentally responsible business models for the repurposing and recycling of EV batteries, bringing value to both companies as well as battery manufacturers and automotive OEMS.

The collaboration also aims to establish responsible repurposing and recycling protocols, to be adopted as industry wide standards, following the waste hierarchy principles of re-use, re-purpose and recycle.

Repurposing EV batteries in stationary systems can extend their life by up to ten years, delivering significant environmental and circular economy benefits. Once these batteries reach the end of their second life, they can then be recycled and the critical minerals recovered for reuse in the production of new batteries, ensuring that valuable resources remain in the UK supply chain.

Altilium has already received its first batch of batteries from Connected Energy, which will be processed at the company’s state-of-the-art recycling facilities in Devon. Using its EcoCathode™ recycling process, Altilium can recover over 95% of the battery metals, including lithium, in a format that can be directly reused in the production of new batteries.

The process also results in a 60% reduction in carbon emissions and 20% lower costs compared to virgin materials, paving the way for the production of more affordable and even cleaner EVs.

Rod Savage, Program Director, End-of-Life Batteries at Altilium, commented: “We’re excited to be working with Connected Energy to advance our shared vision of a circular economy for EV batteries. This collaboration is further demonstration of Altilium’s commitment to ensuring the responsible management of end-of-life EV batteries, working with best-in-class partners across the value chain to support the growth of the entire battery eco-system.”

Matthew Lumsden, CEO Connected Energy, added: “Over the next five years, we will see a rapid increase in the availability of used EV batteries. As an industry, it is critical that we work together to ensure that we move batteries through the value chain in a way that minimises their environmental impact whilst maximising their financial value. This collaboration is an important step in creating a model for true battery circularity.”

Connected Energy’s storage systems are increasingly used across the UK and Europe for applications such as supporting EV charging hubs, cutting energy bills, balancing the grid, and maximising the return on investment from solar arrays. Giving their batteries a second life enables EV manufacturers and other battery owners to further monetise their batteries for several years before they are recycled.

Through this collaboration, Connected Energy hopes to capture more of the residual value of these spent batteries once they reach the end of their second life, while Altilium will gain more visibility of available feedstock for its recycling facilities, including its planned Teesside refinery (ACT 4). The plant will have the capacity to recycle waste batteries from 150,000 EVs a year, producing 30,000 MT of CAM, enough to meet 20% of the expected UK demand by 2030.

Both companies are already part of a £30.1 million Nissan-led project, backed by the Advanced Propulsion Centre, aimed at strengthening the UK’s capabilities in EV battery reuse, recycling and grid balancing.

By promoting the reuse and recycling of EV batteries, Altilium and Connected Energy are helping to build a circular economy for EV batteries in the UK, reducing the UK’s reliance on imported materials and decreasing the carbon footprint associated with battery production and disposal. This in turn supports the UK’s goals to achieve net-zero emissions by 2050.

About Altilium

Altilium is a UK-based clean tech group that will reshape the UK and European automotive supply chain by offering high volume, low carbon domestic sources of cathode and anode materials from recycling waste streams already in circulation, such as end-of-life batteries and mine tailings.

The company’s proprietary EcoCathode™ process converts end-of-life EV batteries and manufacturing scrap into domestic, sustainable, battery precursors, cathode active materials (CAM) and cathode precursor (pCAM) for direct reuse in new batteries.

Altilium’s first mini-commercial plant is currently under construction in Plymouth while its planned Teesside plant will be one of the largest EV battery recycling facilities in Europe. The plant will have the capacity to process scrap from over 150,000 EVs per year, producing 30,000 MT of CAM, enough to meet around 20% of the UK’s expected needs by 2030.

To date, Altilium has secured over £6M in backing from UK government innovation awards, including grants from the Faraday Institutions Battery Challenge and the Automotive Transformation Fund. The company recently completed its Series A funding round with a multi-million pound investment from SQM Lithium Ventures, the corporate venture arm of the lithium business of Sociedad Quimica y Minera de Chile (SQM), one of the world’s leading producers of battery-grade lithium.

For more information go to www.altilium.tech

About Connected Energy

Connected Energy is a world leading innovator of energy storage systems that utilise second-life electric vehicle batteries. The company is one of a few companies worldwide who have the proven technology to repurpose end-of-life batteries and bring them back to life as an energy store.

The company’s E-STOR systems use 24 Renault Kangoo batteries, and its technology is modular and scalable in design, easily adapted to control any EV battery pack.

Its systems can elongate the life of an EV battery pack by up to an additional 10 years and provide grid service revenues, solar optimisation, EV charging support, import capacity avoidance, peak shaving and micro grid balancing services. Systems can provide a positive carbon benefit of 450tCO2e for every 1MWh installed compared with a first life BESS.

The company welcomed a number of strategic investors in 2022, including Volvo Energy and Caterpillar. The company is now developing utility scale battery energy storage sites.

For more information go to www.connected-energy.co.uk

Source: Altilium

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Latest CleanTechnica.TV Videos

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica’s Comment Policy