Tesla began purchasing cathode coils from two second-tier Chinese battery makers in the second half of 2023 and shipping them to its Texas factory in the US to produce 4680 batteries, according to local media.

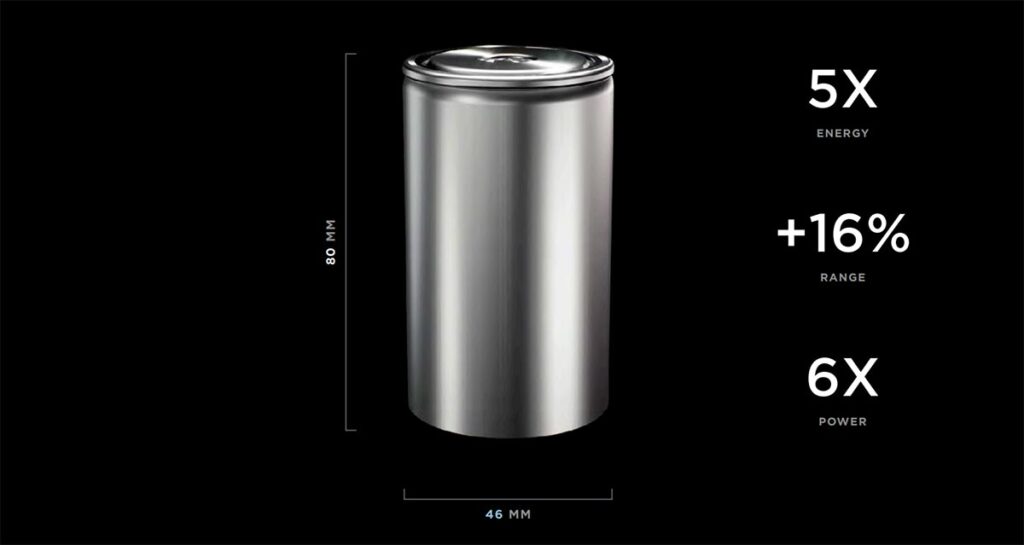

(Screenshot of the Tesla 2020 Battery Day presentation.)

Tesla began purchasing cathode coils from two second-tier Chinese battery manufacturers in the second half of 2023 and shipping them to its Texas factory in the US to produce 4680 batteries, local media outlet LatePost reported today.

Cathode coils are a battery cell component that accounts for about 35 percent of the overall cell cost, the report noted.

The two companies were the suppliers chosen by Tesla last year after it audited the cylindrical battery production lines of several Chinese power battery companies, according to the report.

This practice of sourcing coils from China before making them into batteries could continue into the third quarter of this year, the report said, adding that a person close to Tesla said the EV maker’s battery supplier Panasonic would not start production of 4680 cells until the third quarter.

Tesla had hoped to source cathode coils from companies including CATL and BYD‘s (OTCMKTS: BYDDF) battery unit FinDreams but was turned down, according to LatePost.

These largest battery makers want Tesla to buy complete cells directly, the report noted. CATL and BYD are the top 2 power battery makers in terms of global share.

Sourcing only cathode coils is rare because of the harsh environments and processes required to produce the cells, and typically a battery company will manufacture the entire cell on the same dust-free production line.

In addition, it is costly to source cathode coils from China and ship them to the United States, LatePost noted.

Coils require high sealing for transportation, special packaging, and need to be made into cells in a short period of time, as typical coils develop quality issues after sitting for about 1 week, the report noted.

The reason Tesla went to the trouble of importing the coils was to expand the 4680 battery’s production capacity, LatePost said.

Tesla unveiled the 4680 battery on its 2020 Battery Day, the first battery it designed from the ground up.

Tesla had claimed that with the new design, battery costs could potentially be reduced by more than 50 percent. Tesla has since been trying to put the 4680 battery into mass production, but has encountered bottlenecks in the process.

Tesla announced in mid-June 2023 that the Texas Gigafactory had produced its 10 millionth 4680 battery, and in mid-October announced that production had surpassed 20 million.

After the Cybertruck began deliveries on November 30, 4680 battery capacity remained short, the LatePost report noted.

Tesla’s Texas factory currently has just enough capacity to supply 24,000 Cybertrucks per year, less than one-tenth of Tesla’s previous plan, LatePost said, citing another report last month.

Tesla originally planned to mass-produce the 4680 battery in 2021, but small-scale production didn’t happen until mid-2023.

That’s one of the reasons the Cybertruck’s official launch was delayed from late 2021 to late 2023 after its 2019 unveiling, the LatePost report noted.

Tesla has only achieved dry coating of the anode, but has not yet done so for the cathode, so it needs to outsource common cathode materials to produce batteries, the report said.